At Rapier Electronics, we pride ourselves on being a leader in printed circuit board assembly (PCBA).

We are trusted providers of PCBA for industries such as;

Our commitment to superior quality and modern techniques makes us one of the most highly sought-after PCBA providers in South Australia. We continually invest in our facilities to make sure we are using the latest and best methods for your products.

Modern equipment and methods

There are various high-quality methods we can use to assemble your printed circuit boards. Surface mount technology (SMT) and through-hole assembly are our specialities.

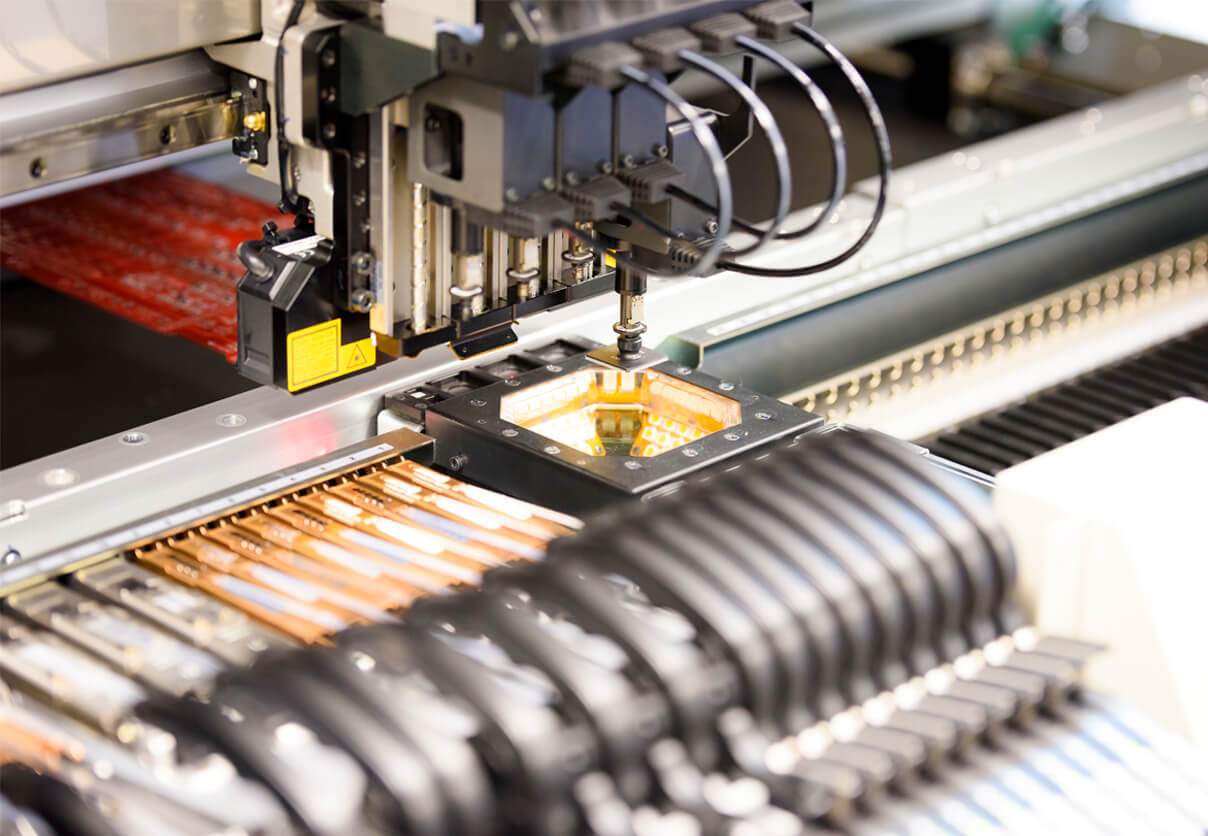

We have invested in a high-speed, high-capacity line of automated ‘pick and place’ machines and stencil printers – an automated SMT assembly line.

This technology enables us to offer SMT assembly solutions for small R&D and prototype assemblies, right through to full production. No matter what volumes you need for your project, we can provide it.

Quality and experience

Quality is our highest priority to ensure high-level, reliable and consistent performance from every product. All our circuit board assembly work is inspected to IPC-A-610 standards.

Our capabilities include:

- chip packages down to 01005 size

- fine pitched leaded components

- leadless components; BGA’s, solder-charged/butt-joint terminations, etc.

- RoHS and non RoHS soldering solutions.

Our machines can also load PCBs of all materials, shapes and sizes – up to 1.8 metres in length.

Our quality re-flow systems and our years of experience in RoHS products ensure that customers always receive products of the highest standard and reliability.

Additionally, our highly skilled assembly team has vast experience loading through-hole assemblies and operating wave-soldering technology. This experience includes:

- RoHS and non-RoHS wave soldering

- Certified hand-solder specialists

- Wire-to-PCB soldering

- PCB modification including rework and wire links etc.