At Rapier, we can offer you highly flexible printed circuit board manufacturing processes, backed by an experienced management team and vast industry knowledge.

You can request any combination of our individual printed circuit board manufacturing processes – not just full-scale production.

Whether your product requires a simple or complex modification, part replacement, component encapsulation or conformal coating, we can help.

We have the ultimate solution to streamline your project development from prototyping to volume production.

Services we offer

Our difference

As well as providing highly customised services, we also promise an easy and reliable process from start to finish. It’s our differences that make this possible:

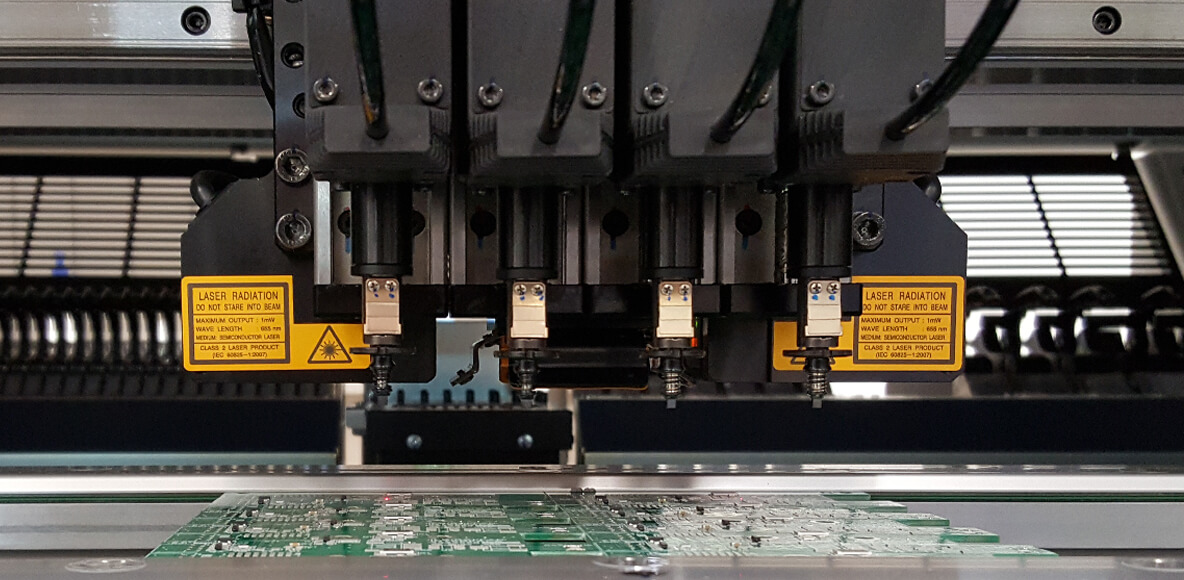

- We continually invest in the latest technology to give you the best possible result.

- We make quality our highest priority to get the best performance from every part.

- We can deliver low or high-volume production, depending on your needs.

- Our Rapier team of qualified, skilled professionals has decades of experience.